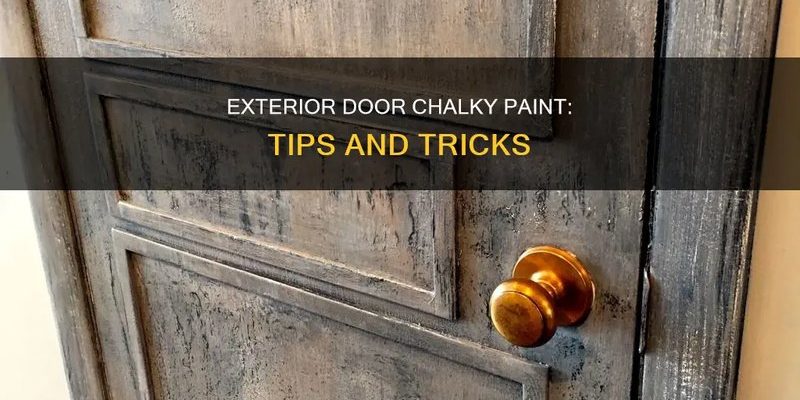

Here’s the thing: your exterior door hardware is built to handle the elements—rain, snow, freezing wind, and intense heat. But when it comes to the slow, steady attack of ultraviolet (UV) rays from the sun, even the toughest finishes can take a hit. That chalky residue is a sign your hardware is reacting to the sunlight in a surprisingly chemical way. Let me explain what’s really happening, how it affects everything from style to security, and what you can actually do about it.

What Causes That Chalky Residue on Door Hardware?

At first glance, the residue might seem like ordinary dust or leftover cleaning product. But the real story is a bit more scientific. Most modern door hardware—whether it’s made of brass, stainless steel, or aluminum—comes with a special finish. This finish isn’t just for looks; it serves as a shield against weather and fingerprints. But here’s the catch: UV light from the sun can slowly break down this protective coating through a process called photodegradation.

Over time, as UV rays hit your hardware, they start breaking apart the molecules in the finish. Imagine the finish as a sturdy raincoat for your metal parts. UV light acts like invisible scissors, snipping away at that coat little by little. Eventually, tiny bits of the finish lose their tight structure, turning into a dry, flaky powder—aka, the chalky residue you’re seeing. This effect is most obvious on south- or west-facing doors that get direct sun for hours a day.

How Sunlight (UV) Affects Different Hardware Finishes

Not all finishes are created equal. For example, a polished brass handle reacts very differently to sunlight than a matte black aluminum lever. Let’s break it down:

- Clear lacquer coatings are common on shiny brass or bronze hardware. They look great but tend to break down fastest in strong UV light, often leaving behind a white or yellowish film.

- Powder-coated finishes are used for colorful, matte, or textured hardware. They hold up better, but after years of sunlight, even powder coat can “chalk” and lose its color.

- Stainless steel is less likely to chalk but can still develop a light, dusty film from the slow breakdown of passivation layers or leftover residues from manufacturing.

Honestly, it can feel like an unfair fight when you realize your expensive Baldwin or Schlage handles are aging faster simply because they’re in the sun’s spotlight. If you’ve also tried “universal” hardware from a hardware store, you might see less residue—these often use tough, less decorative coatings that don’t break down as quickly (but might not look as fancy).

Environmental Factors That Make Chalky Residue Worse

You might be wondering why your neighbor’s front door still looks shiny while yours is turning into a powdery mess. A big part of the answer comes down to location and the elements. Here’s what speeds up the problem:

- Direct sunlight: South- and west-facing doors get hit hardest. Even a partial overhang or shade from a tree can slow down the chalking process.

- Rain and humidity: Moisture combines with UV to break down finishes faster. Water lets chemicals in the air react with the weakening coating, speeding up residue buildup.

- Salt air (near the ocean): If you’re by the coast, salty breezes can make hardware finishes age in dog years—especially if you have any tiny scratches or chips already.

It’s almost like your door hardware is fighting a three-front battle: sunlight, water, and air pollution. Over time, chalking can show up earlier and look worse if you live in a harsh climate or have an uncovered entryway.

Why Does This Matter? Problems Beyond Appearance

Sure, the main concern at first is how ugly that chalky film looks—nobody wants a white, crusty doorknob greeting their guests. But there’s more at stake than curb appeal.

Security can actually take a hit. Once the finish is gone, the underlying metal (like brass, zinc, or steel) is left exposed. If moisture gets in, you could see rust, corrosion, or pitting. For smart locks or keypads, that residue can sneak inside the mechanism and cause sticky buttons or glitchy performance, leading to missed codes or lockouts.

Plus, if you keep cleaning the residue with harsh chemicals or scouring pads, you’ll accelerate the breakdown. It’s a little like using sandpaper on your phone screen—eventually, you’ll wear down protective layers and make things worse.

Pro tip: The less you scrub, the longer your hardware lasts. Use gentle cleaners and avoid anything abrasive!

Can You Prevent Chalky Residue From UV Exposure?

It’s natural to ask if you can stop this process entirely. While you can’t turn off the sun, you can slow down the effects of UV light on your exterior door hardware.

- Install shade where you can: Adding an awning, porch roof, or even a potted plant can reduce direct exposure by half.

- Choose hardware with UV-resistant finishes: Brands like Schlage and Kwikset now offer coatings labeled for “coastal” or “UV protection.” Look for those features when you replace old hardware.

- Use gentle, regular cleaning: Wipe hardware with a damp, soft cloth. Avoid chemical cleaners unless the manufacturer recommends them. Some people use a tiny dab of car wax for added protection, but test it on a hidden spot first.

- Reseal or refinish: If your finish is already damaged, you can clean off the chalk, sand lightly, and apply a clear outdoor-grade lacquer. Just make sure it’s meant for metal and UV exposure.

Honestly, if your hardware is several years old and the chalky buildup keeps coming back, it might be time to swap it out. Modern UV-protected versions last much longer (and save you cleaning headaches).

Comparing Universal vs. Brand Name Door Hardware

There’s lots of talk about whether “universal” replacement handles from the hardware aisle hold up better than name-brand pieces from Schlage, Baldwin, or Kwikset. Here’s what I’ve noticed after years of dealing with both:

- Universal hardware: Tends to use rugged, no-frills finishes that don’t look as shiny but resist “chalking” a bit better. They’re great if you want low maintenance and don’t mind a basic look.

- Brand name hardware: Schlage and the like offer beautiful finishes (satin, bright brass, antique bronze) that look stunning at first. However, unless you get the UV-protected versions, they’re more prone to chalky residue in direct sun.

So, if you want the “wow” factor, go for the branded hardware but keep it shaded. If you need a set-it-and-forget-it solution, universal hardware might last longer before chalking becomes an issue. Either way, placement and care matter more than the sticker on the box.

Is Chalky Residue Ever a Sign of a Bigger Problem?

Most of the time, chalking is a cosmetic, slow-moving issue. But there are cases where it’s a warning sign something’s going wrong inside your hardware.

If your lock suddenly starts feeling gritty, sticking, or sluggish, it could mean the residue has mixed with dust or moisture and is gumming up the mechanism. For electronic locks, residue can creep into seams or battery compartments, leading to sync issues or battery drain, especially if you see white dust near the keypad or under the cover.

Don’t ignore bigger color changes, bubbling, or deep corrosion marks. That’s a sign water has gotten under the finish, and the metal beneath is starting to oxidize. In rare cases, it could weaken the structure enough to make your lock less secure—or even jam completely.

How to Clean and Maintain Exterior Door Hardware the Right Way

Let’s walk through some simple steps to keep your hardware looking (and working) its best:

- Step 1: Dust lightly with a soft, dry cloth to remove loose powder. Don’t scrub—the idea is to lift, not grind, the residue off.

- Step 2: Wipe with gentle soap and water. Mix a few drops of mild dish soap with water, then use a damp cloth to clean the surface.

- Step 3: Dry completely. Moisture speeds up finish breakdown, so always dry every nook and cranny, especially around screws and seams.

- Step 4: Apply a protective coat. Consider a non-abrasive, UV-protective wax (like those used for cars) for an extra layer. Test first to make sure it doesn’t change the color or texture of your handle.

If you’re troubleshooting stubborn stains or hardware that’s already pitted or rusty, it might be time for a reset—either refinishing or replacing the hardware altogether. Syncing new hardware with smart lock systems? Always follow the pairing instructions to avoid battery or code issues down the line.

Final Thoughts: Getting Ahead of the Chalky Residue Problem

It’s easy to overlook exterior door hardware, but that small, chalky buildup is more than just house dust. It’s your hardware telling you that sunlight—mainly UV rays—is winning the long game. Whether you use a Schlage, Kwikset, or a run-of-the-mill universal handle, all hardware takes a hit from the sun over time.

The fix isn’t complicated: protect from sun where you can, clean gently, pick UV-resistant finishes, and don’t wait too long to address early signs of wear. That way, your hardware will keep looking sharp, working smoothly, and welcoming you home—without leaving any powdery surprises behind.