Here’s the thing: not all screws are created equal, especially when it comes to outer doors. Whether you’re installing a Schlage deadbolt, a Kwikset handle, or any other brand, the right screw makes a huge difference. Making the wrong choice can mean early repairs, or even worse, a security risk. Let me explain what to look for, why corrosion resistance matters, and how to spot the right screw for the job.

Why Screw Selection Matters For Exterior Door Hardware

Think of your front door as the line between your safe indoor space and the unpredictable outdoors. Every piece of hardware on that door—locks, handles, strike plates—is only as strong as the screws holding it in place. If those screws can’t handle rain, snow, or salty air, they’ll rust, weaken, and eventually break. That means even the toughest deadbolt or handle won’t do much good.

Choosing proper screws isn’t just about strength, though. Exterior doors are exposed to a lot, from sticky summer humidity to icy winter mornings. Corrosion-resistant screws keep your door hardware firmly attached, reduce maintenance, and extend the life of your locks and handles. Do it right once, and you won’t have to think about it for years.

You might be wondering: “Don’t all screws look the same?” Not really. Some are made from cheap steel that rusts as soon as it meets moisture. Others are designed for indoor use where corrosion isn’t an issue. When you’re shopping for replacements or new hardware, it pays to pay attention to what kind of screws you’re really getting.

Types Of Screws Commonly Used For Exterior Doors

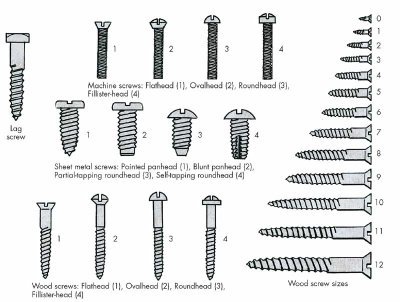

Walking down the hardware aisle, it’s easy to get overwhelmed—so many screws, so many finishes, so many promises. Let’s break down the most common types you’ll see for exterior door hardware, and when to use each.

- Steel Screws (Standard): These are cheap, easy to find, and often included with hardware kits. Here’s the problem: unless they’re coated or made specifically for outdoor use, they’ll rust in no time if exposed to the elements.

- Stainless Steel Screws: These are the top choice for most exterior door hardware. Stainless steel resists rust and corrosion, even in harsh weather. If you live by the coast or in a rainy zone, these are your best friend.

- Brass Screws: Brass resists corrosion well, especially in less brutally wet climates. They’re common in decorative hardware, and you’ll notice them on older doors. Just be careful—not all brass screws are as strong as steel for heavy-duty locks.

- Coated Or Galvanized Screws: Some steel screws are coated with zinc, ceramic, or other rust-resistant layers. They can be a solid choice, but over time, that coating can chip—once that happens, rust can creep in.

Honestly, if you want to set it and forget it, stainless steel or high-quality coated screws are the way to go. Pay a little extra now, save a lot of hassle later.

How Corrosion Resistance Protects Your Door Hardware

You might be asking, “How much does corrosion resistance really matter?” Here’s the short answer: it matters a lot. Corrosion isn’t just about ugly orange rust stains on your screw heads. When screws rust, they actually get weaker, which means your lock, handle, or hinge can loosen or fail over time—even if the rest of your hardware is still in perfect shape.

Think about how many times your front or back door gets opened and slammed shut. Every time, there’s a little movement that puts stress on those tiny fasteners. If they’re rusted, they can snap more easily or simply crumble apart. That can mean a lock that won’t stay tight, or a strike plate that pulls right out of the frame.

Here’s a tip: If you live near saltwater, humidity or salty air can corrode even coated screws fast. Always check for “marine grade” stainless steel for the best protection.

It’s not just about the screw, either. Rust can bleed onto your hardware, causing pitting or staining that’s tough to clean. So, investing in corrosion-resistant screws is a double win: your hardware lasts longer, and your door looks better.

Spotting The Right Screws: What To Look For

Now for the nitty-gritty: how do you actually know if you’re choosing the right screws for your exterior door hardware? Start with the packaging. Look for wording like “stainless steel,” “corrosion-resistant,” or “weatherproof.” If you see “interior use only,” put it back. Brands like Schlage, Kwikset, and Yale often include proper screws with their exterior door locks, but it never hurts to double-check.

Here’s what to watch for:

- Material: Stainless steel is preferred. If you’re looking at a shiny coating but the screw feels lightweight, it could be coated brass or zinc—double-check the label.

- Finish: Some coated screws will say “galvanized” or “ceramic-coated.” These are okay for most climates, but not as sturdy as full stainless steel in wet conditions.

- Length: For door frames and strike plates, go longer—at least 2.5 to 3 inches. Short screws pop out easily, especially after a few slams. Longer ones bite into the frame and add security.

- Head shape: Most door hardware uses flat or oval heads for a flush finish. Use what fits your hardware best to avoid wobbly parts.

Let me explain: even the best deadbolt is only as good as the screws holding it. I once replaced a rusty strike plate screw with a cheap, short steel one, and it pulled out after a month. Swapped it for a long stainless steel screw—problem solved for good.

Comparing Screw Materials: Pros And Cons

Let’s lay it out side by side. Sometimes seeing the differences in a table makes things clearer:

| Material | Strength | Corrosion Resistance | Cost | Best For |

| Standard Steel | High | Low (rusts easily) | Low | Indoor use, temporary fixes |

| Stainless Steel | Medium-High | Very High | Medium-High | Exterior doors, wet climates |

| Brass | Medium | Medium-High | Medium | Decorative hardware, mild climates |

| Galvanized/Coated Steel | High | Medium | Low-Medium | Outdoor use if not too wet |

Here’s the bottom line: stainless steel usually wins for long-term outdoor use, followed by coated screws for budget or less-exposed locations. I always keep a handful of 3-inch stainless screws around—they’re great for quick fixes and sturdy enough for almost any brand of exterior door hardware.

Tips For Installing Exterior Door Hardware With The Right Screws

Getting the right screws is step one, but putting them in properly is just as important. A good screw in the wrong hole or at the wrong angle can still let down your door hardware. Here’s what I’ve found works every time:

- Pre-drill pilot holes, especially if you’re using hardwood doors or frames. This keeps screws from splitting the wood or going in crooked.

- Use the correct bit for the screw head—stripping the head makes future replacements a pain.

- Tighten firmly, but don’t over-torque. Over-tightening can actually snap softer brass or coated screws or strip the hole.

- Double-check alignment on hardware like strike plates and hinges. If the holes are off, your door won’t close smoothly and screws will wear unevenly.

If you spot rust or movement a few months after installation, take a look. Sometimes a screw loosens up just from door slamming. Tighten it, and swap any rusty screws for stainless steel while you’re at it—you’ll thank yourself next winter.

Common Mistakes When Choosing Screws For Door Hardware

Even the handiest DIYers slip up here and there. Some mistakes pop up again and again, especially for folks new to home repairs. Let me save you the trouble:

- Using leftover screws from that random jar in the garage. Odds are, they’re not meant for outdoor use—and they may be too short or thin for your door hardware.

- Choosing appearance over strength. Decorative screws might look nice, but if they’re weak or not corrosion-resistant, your hardware will suffer.

- Assuming the included screws are best. Some hardware kits save a buck by tossing in subpar screws. Don’t be afraid to upgrade to *better* ones if you’re not sure.

- Ignoring length and grip. Short screws are a security risk; always go for 2.5-inch or longer, especially on strike plates and hinges.

So if you’re struggling with a loose lock or rusting hardware, take a closer look at your screws. Upgrading takes less than five minutes and can make your setup last for years.

When To Replace Screws: Signs Of Trouble

How do you know when it’s time to swap out your exterior door hardware screws? Sometimes it’s obvious—stripped heads, rust flakes, or full-on breakage are dead giveaways. But there are subtler signs, too. If the lock or handle feels loose, or you spot orange streaks around the screws after a rainy week, that’s a big hint.

Other signs it’s time for fresh, corrosion-resistant screws:

- The screw turns easily without tightening—that means the grip is shot.

- You spot swelling or soft wood around the screw holes from moisture getting in.

- The screw head snaps off during removal (a classic sign of corrosion and weak metal).

Don’t wait for a total failure. I’ve seen more than a few beautiful entry doors ruined by a couple of rusty screws. Swapping them out is a quick, cheap fix—and honestly, it’s satisfying to know you did it right.

Final Thoughts: Secure, Corrosion-Resistant Screws Make All The Difference

If there’s one lesson here, it’s that the small stuff matters. Picking the right, corrosion-resistant screws for your exterior door hardware isn’t flashy, but it’s what keeps your locks strong, your handles solid, and your home secure. Whether you’re working with a top brand like Schlage or a no-name generic, always double-check that those screws are built for the outdoors.

Don’t let a rusty fastener undo your hard work. Choose stainless steel or the best coated screws you can find, make sure they’re long enough, and install them with care. It’s a little extra effort up front, but it keeps your doors trouble-free for years. In the end, the right screw is the quiet hero of every solid, secure doorway.