So, how do you figure out which screw is right for your particular hardware component? Let’s break it down into manageable steps. It’s not as complicated as it sounds. With a bit of guidance, you’ll be matching screws to your projects like a pro, ensuring everything fits snugly and securely.

Understanding Screw Types

When we talk about screws, we’re essentially discussing a variety of fasteners that help hold objects together. There are many types of screws, but they can generally be divided into a few categories based on their head type, thread design, and the material they’re made from.

Common screw types include:

- Wood screws

- Machine screws

- Sheet metal screws

- Self-tapping screws

- Lag screws

Each type has its specific use case. For instance, wood screws are designed to be driven into wood without splitting, while machine screws are used with nuts or tapped holes and often require a washer for a secure fit. Here’s the thing: understanding the basics of these types helps you avoid costly mistakes.

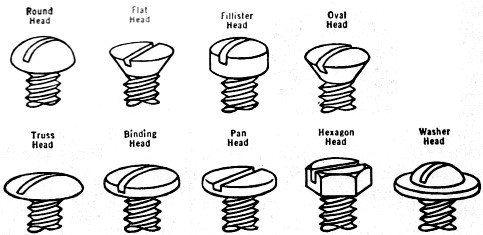

Identifying Screw Head Types

The head of a screw is the part that you can see and grab onto when you’re turning it. Various head styles exist, and each serves a different purpose. Here are a few common types:

- Flat head: Sits flush with the surface. Great for a smooth finish.

- Phillips head: Cross-shaped, allowing for better grip with a screwdriver.

- Hex head: Uses a wrench. Ideal for heavier applications.

- Round head: Provides a decorative look but isn’t as strong.

Picking the right head type is crucial. For example, if you’re assembling a piece of furniture, you might want a flush finish, so a flat head screw works best. On the other hand, if you need something sturdy, a hex head might be your best bet.

Understanding Screw Sizes

Screw sizes can feel overwhelming at first, but they’re key to ensuring a match with your hardware components. The size of a screw typically refers to its diameter and length. Let’s break this down:

– Diameter: This tells you how thick the screw is. Common measurements include

– Length: How long the screw is, often measured in inches or millimeters. You usually want enough length to penetrate through the materials you’re joining.

When selecting a screw, remember that the right length matters. A screw that’s too short won’t hold securely, while one that’s too long can poke out the other side or cause damage.

Thread Types and Their Importance

The threads on a screw are what makes it effective at gripping materials. Different applications require different types of threads. Most screws fall into two categories: coarse threads and fine threads.

– Coarse threads: These have larger spaces between the threads and are generally used for wood or softer materials. They grab hold quickly and are less likely to strip.

– Fine threads: These are better for harder materials like metal. They provide better tension and can hold objects very tightly.

You might be wondering why thread type matters so much. Simply put, choosing the wrong thread for your project can lead to loose connections or stripped holes.

Material Matters: Choosing the Right Screw Material

The material of the screw plays a significant role in its function and durability. Common screw materials include:

- Steel: Strong and durable, often coated to prevent rust.

- Stainless steel: Resistant to corrosion, making it perfect for outdoor projects.

- Brass: Great for a decorative finish but not as strong.

- Plastic screws: Lightweight and resistant to rust, mainly for light-duty applications.

Choosing the right material depends on where and how you’ll use the screws. If you’re fixing something outdoors, stainless steel would be your best choice due to its resistance to rust.

Checking Compatibility with Hardware Components

Before you head to the store or order screws online, it’s essential to consider the hardware components you’re fastening together. Different materials may require different screws, even if they seem similar.

For instance, if you’re working with a hardwood surface, you should opt for screws specifically designed for wood. These have a sharper tip and deeper threads to grab better. On materials like metal, self-tapping screws are often used because they can create their threads as they’re driven in.

You might want to consider using a pilot hole if you’re unsure. By pre-drilling holes, you can help prevent splitting and make it easier to screw in your fasteners straight.

Common Mistakes to Avoid When Selecting Screws

Even seasoned DIYers can make mistakes when choosing the right screws. Here are a few common pitfalls to watch out for:

1. Not matching the screw type to the material: Always consider the type of surface you’re working with.

2. Ignoring the length and diameter: Measure accurately to ensure a proper fit.

3. Underestimating the importance of head type: Don’t just choose what looks good; function matters, too.

4. Not using pilot holes: This is especially crucial for harder woods or dense materials.

By keeping these mistakes in mind, you can streamline your selection process and avoid headaches down the line.

Final Thoughts on Choosing the Right Screw

Identifying the proper screw type for specific hardware components might feel daunting at first, but with a bit of knowledge, you can navigate the hardware store like a pro. From understanding screw types and sizes to ensuring compatibility with your materials, each step is vital.

Remember, choosing the right screw not only ensures a secure connection but also prolongs the life of your project. So next time you’re standing in the aisle, take a moment to review these points. Happy building!