So, what actually happens when a shear line in a lock cylinder wears out? Imagine the shear line as the invisible finish line your key needs to align so the lock will turn smoothly. When it wears down, it’s a little like trying to fold a playing card along a crease that’s gone soft; nothing really lines up, and suddenly, what should be simple feels much harder. If you’re troubleshooting sticky keys, weird jams, or just want to keep your home secure, knowing how to identify a worn shear line is a skill you’ll want in your back pocket.

What Is the Shear Line in a Lock Cylinder?

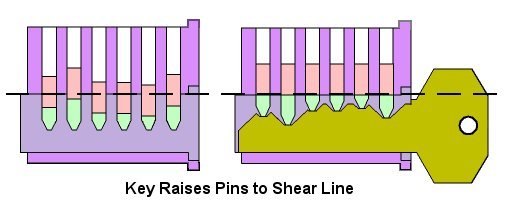

To understand if your lock’s shear line is worn out, let’s start with the basics. The *shear line* is the imaginary boundary inside the lock where the plug (the part you turn) meets the lock body (or shell). When you insert the right key, the pins inside line up perfectly along this boundary—letting the cylinder turn and the lock open. Picture stacking blocks so they’re flush on top; if there’s a bump or dip, things won’t move as they should.

When the shear line is in good shape, your key glides in and the lock turns with that satisfying click. But if you’ve noticed the key feels gritty, or you have to jiggle it just right, the shear line could be worn. Over years of daily use—think endless unlocking, worn keys, temperature changes—the delicate pins and metal edges where the plug and shell meet can start to round off or deform.

Here’s the thing: you don’t have to be a locksmith to spot the signs. Even on popular brands or universal lock cylinders, the symptoms are usually easy to notice once you know what you’re looking for. When the shear line is worn, it’s not just about annoyance. It can lead to your lock being bypassed more easily or failing completely, which is the last thing anyone wants on a hectic day.

Common Signs of a Worn Shear Line

You might be wondering, “How do I know it’s the shear line and not just a sticky key or dead battery in the remote?” Honestly, it’s not always obvious—locks and remotes can both act up for different reasons. But there are some classic clues that point straight to the shear line.

- Key sticking: If your key’s getting harder to insert or remove, or if you have to wiggle it to get the lock to turn, that’s a red flag.

- Uneven turning: Pay attention to resistance. If the lock feels gritty, rough, or gets “caught” halfway through turning, the pins may not be lining up with the worn shear line.

- Partial unlocking: If the lock sometimes turns but doesn’t fully disengage, it could be because the plug isn’t clearing the shear line smoothly.

- Visible metal shavings: Take a close look at your key after using it. If it’s suddenly coated with tiny, shiny metal bits, you might be seeing the lock’s innards wearing away.

These issues usually pop up more on high-traffic doors—front doors, office doors, or anywhere locks get used a ton. If you’ve replaced the batteries in your smart lock remote or tried all the obvious troubleshooting steps and the problem sticks around, the shear line deserves a closer look.

How to Safely Inspect the Shear Line Yourself

Let me explain: you actually can check for a worn shear line at home, but it helps to go slow and be careful. Start by removing the lock cylinder from the door. For most brands like Schlage or Kwikset, that’s just a matter of undoing a few screws and sliding out the cylinder. Make sure you’ve got the right code (if you have a smart lock or electronic remote) and have disconnected any battery power if the lock is part of a synced system.

Once the cylinder is out, shine a bright light into the keyway. Try inserting your key and see how the pins align. With a worn shear line, you might spot:

- Pins sitting unevenly: Some pins may hang lower or higher than the rest, even with the key fully inserted.

- Rounded edges: Instead of sharp, clear boundaries where the plug meets the shell at the shear line, you’ll notice smoother, worn-down curves.

- Visible gaps: If you can see small spaces or even slivers of light along the edge, that’s another giveaway.

If you’re not sure what you’re seeing, snap a clear photo—sometimes, zooming in makes subtle wear easy to spot.

Don’t be afraid to use a magnifying glass, either. These tiny details matter. If you spot classic signs of wear, consider replacing the lock or bringing it to a professional for repair.

Why the Shear Line Matters for Security

Here’s the thing: a worn shear line isn’t just an inconvenience—it’s a real risk. The shear line is the lock’s last defense against picking, bumping, or forced entry. When it’s in good shape, it keeps the lock secure by making sure only the right key can turn the cylinder. But as it wears down, the pins can slip out of place more easily.

Let’s say someone tries to pick the lock or use a code-bumping tool. With a crisp shear line, the pins will only align if the right cuts are present on the key. But with a worn line, even an incorrect key or makeshift tools have a better chance of lining up just enough to turn the cylinder. That’s a big problem if home security matters to you.

On older lock brands, universal lock cylinders, or doors that see tons of use, weakened shear lines pop up faster. If you’ve ever noticed your remote lock system “sync” fails or the manual override feels gritty, that can be a sign the hardware itself is letting you down. Keeping the shear line in good shape is just as important as changing dead batteries or updating digital codes.

Comparing Worn Shear Lines to Other Lock Problems

Let’s be honest—locks can act up for all sorts of reasons. So, how do you know you’re dealing with a worn shear line and not something else, like a worn key, a loose tailpiece, or dead batteries in your electronic remote? Here are some comparisons to help you sort out the cause:

- Worn key vs. worn shear line: If you have multiple copies of the key and all feel sticky or rough, the lock’s shear line is likely at fault.

- Electronic locks: If resetting, re-syncing, or swapping batteries in your smart lock doesn’t fix hand-turn issues, mechanical wear is probably to blame.

- Loose locking hardware: If the whole lock cylinder turns in the door or the mounting screws are loose, you’ll need to tighten things up before blaming the shear line.

The takeaway? Always double-check the basics first. Rule out easy fixes before diving into a lock cylinder teardown. If your troubleshooting steps (like reset, repair, or sync) don’t work, then take a closer look at the shear line itself.

When to Replace or Repair a Worn Shear Line

Alright—so you’ve looked inside, seen the rounded pins or rough metal, and you’re sure the shear line is the problem. When should you replace the lock, and when might a repair work?

- Heavy wear or damage: If you see deep grooves, shiny worn patches, or pins that don’t move smoothly, replacement is usually the safest bet. Locks with bad shear lines can fail suddenly, leaving you locked out or vulnerable.

- Minor wear: If the problem is just starting (a little roughness, minor pin misalignment), a qualified locksmith can sometimes re-pin the lock or swap worn parts—especially on quality brands like Schlage or Yale.

- Universal cylinders: Standard, non-branded cylinders are often cheap enough to just replace, rather than repair.

If your lock is part of a battery-powered smart lock or uses a digital remote, make sure the new cylinder is compatible with your system’s code or sync requirements. Sometimes, it’s worth upgrading to a higher-security cylinder at the same time as you replace a worn shear line.

Tips to Prevent Shear Line Wear in the Future

Once you’ve tackled a worn shear line, you probably want to avoid dealing with it again anytime soon. Good news: a few simple habits go a long way.

- Use well-cut keys: Keys that are worn, bent, or chipped put extra stress on the pins and shear line inside your lock cylinder. Always use clean, sharp keys.

- Keep it clean: Dirt, dust, and old lubricant can grind away at the shear line. Spray a little lock lubricant (not oil) into the keyway every six months or so.

- Control access: The more copies of your key out there, the more chances for damage. Stick with quality duplicates and keep spares to a minimum.

- Don’t force your lock: If the key doesn’t turn easily, don’t muscle it. Stop, troubleshoot, and check for issues before pushing through. Forcing the lock wears the shear line even faster.

Think of your lock like any other moving machine—regular maintenance makes it last, and careful use keeps it reliable.

Choosing the Right Cylinder: Universal vs. Brand-Specific

If you decide to swap out a cylinder because of a worn shear line, you’ll run into options: universal cylinders or brand-specific models. Here’s what to know:

- Universal cylinders: These fit a range of lock bodies and can be cut to work with many different keys. They’re cheap and easy to find but may not match the build quality of top brands. If you’re in a pinch and need a quick reset, they can work well.

- Brand-specific cylinders: Kwikset, Schlage, Yale, and other big names design cylinders for their own locks. These often use stronger pins, tighter tolerances, and advanced anti-pick features—making them a better bet for long-term security and smoother operation.

If your lock also uses a remote, code, or battery backup, make sure any new cylinder will sync and pair properly with your existing system. Check the compatibility on the box or manual, and don’t hesitate to call the brand’s support line if something feels confusing.

Finishing Up: Staying Safe and Secure

Spotting a worn shear line is one of those small skills that pays off big—saving you from lockouts, security headaches, or costly emergency repairs. Whether your lock cylinder runs on pure old-school metal or is part of a fancy smart lock system with code, remote, or sync features, the basics haven’t changed: keep the shear line sharp, keep your keys in good shape, and don’t ignore those subtle warning signs.

If you’re ever in doubt, check with a pro or bring your lock cylinder to a local locksmith for a second opinion. You might even pick up a few new troubleshooting tricks along the way. In the end, a well-tuned lock is more than just a convenience—it’s your daily peace of mind, one click at a time.