Here’s the thing: not all drills, bits, or accessories are up for this job. And speaking from experience, trying to “make do” with the wrong tool is just asking for frustration. The good news? With a few smart choices—like grabbing the right carbide-tipped bits for steel or a hammer drill for reinforced doors—you can get pro-level results, even if you’ve never drilled through anything tougher than pine.

Let me walk you through which tools matter most for precision drilling on tough exterior door materials. Whether you’re comparing brands like DeWalt, Bosch, or Milwaukee, or just trying to figure out what sets a hammer drill apart from a regular driver, I’ll lay it all out simply so your next project goes smoothly.

What Makes Exterior Doors Challenging to Drill?

Exterior doors aren’t all built the same, and that’s where the trouble starts. Unlike interior doors, which are often hollow-core and made from lightweight wood or MDF, exterior doors need to hold up against weather, would-be intruders, and years of slamming. You’ll find doors made from:

- Steel (sometimes with a foam core)

- Fiberglass (lightweight, but surprisingly tough and prone to cracking)

- Solid-core wood (heavy and dense)

Each material brings its own headaches. Steel dulls regular bits in no time and heats up quickly, which can warp or burn the surface. Fiberglass might look forgiving, but it chips and splinters if your bit isn’t razor sharp. With wood, you need power—plus a steady hand to avoid “tear-out” around the hole.

Precision matters for more than just looks. A slightly off-center hole can make it impossible to sync up your deadbolt, or leave an ugly gap that water slides right into. The key is picking the right tools for each material and job—so you don’t end up wishing you’d just called a locksmith.

Choosing the Best Drill for Exterior Door Work

Let’s start with the main tool: your drill. There’s a world of difference between a bargain cordless drill and a quality hammer drill or a corded model from a brand like DeWalt or Bosch. Here’s what to consider.

First, think about power and control. Dense materials like steel and hardwood need a drill that won’t bog down halfway through. Look for at least an 18V cordless drill, or a corded drill rated at 6 amps or higher. Hammer drills add a percussive action that helps drive the bit through stubborn material—especially handy for reinforced steel doors. Don’t worry, you can turn the “hammer” mode off for wood and fiberglass.

Second, focus on variable speed and a reliable clutch. Lower speeds keep steel from overheating, while a clutch prevents overdriving screws or stripping out wood. Honesty time: I’ve tried to “make do” with a basic home-store drill and lived to regret it. Investing in a midrange Bosch or Milwaukee saves time and bit replacements in the long run.

Lastly, if you’re working overhead or in tight spaces, weight and grip comfort matter. Pick a drill that feels balanced in your hand—you’ll thank yourself after the fifth pilot hole.

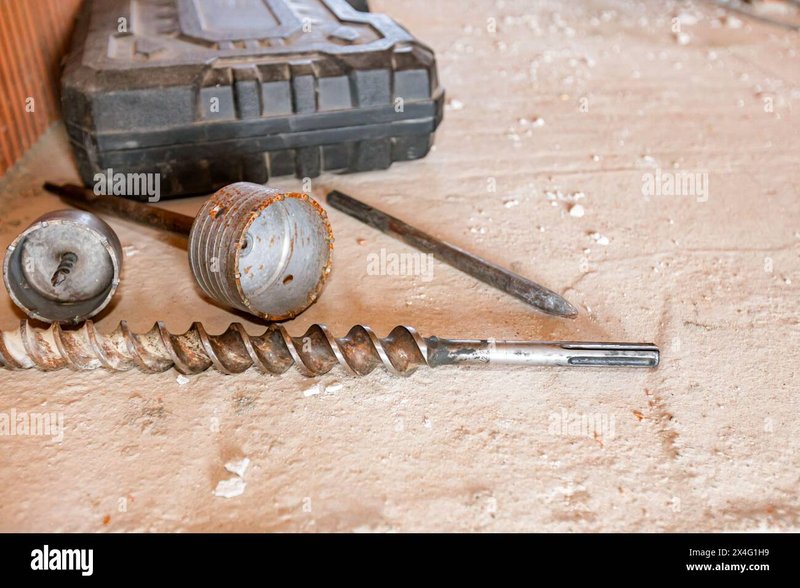

Drill Bits: Matching the Bit to the Material

Even the best drill won’t help if you’re using the wrong bit. Exterior door materials ruin cheap or dull bits almost instantly. Here’s a quick guide to what works for each type:

- Steel doors: Use cobalt or titanium-coated bits. Carbide-tipped bits from brands like Bosch or DeWalt last even longer and resist heat build-up. Start with a small pilot hole, then work up to your final size.

- Fiberglass: Brad point bits are your best bet—they cut clean holes with minimal splintering. For larger holes (like for a deadbolt), use a hole saw specifically rated for fiberglass and go slow.

- Solid wood: High-speed steel (HSS) or spade bits work well for most jobs. If you need a really clean cut (for visible hardware or tight-fitting locks), step up to forstner bits—just watch out for the torque.

Let me explain why this matters: A regular wood bit will barely scratch steel, and a masonry bit might just bounce around on fiberglass. Matching the right bit to your door material saves time, avoids damage, and makes the job a lot less stressful.

Tip: Always let your drill bit do the work—don’t force it. If you see smoke, feel resistance, or smell burning, back off and let everything cool down before continuing.

Accessories That Make Drilling Easier and Cleaner

You might be wondering, “Isn’t the drill and bit enough?” Honestly, a couple of smart accessories can make a world of difference—especially if you only get one chance to drill a perfect hole in an expensive door.

First, consider a drill guide or centering jig. These clamp onto the door and keep your drill bit from wandering off-center. It’s like giving your drill some training wheels, and it’s a lifesaver for people who don’t drill for a living.

Next, masking tape comes in handy, especially for fiberglass or wood. Stick a square where you plan to drill—this helps prevent surface chipping and gives you a clear spot to mark your hole. For steel, a center punch (just a sharp metal tool you tap with a hammer) makes a dimple for your drill bit to start in, so it doesn’t slide around.

Another thing: Keep a vacuum or dust shroud nearby. Drilling into a heavy door creates a surprising amount of dust and debris, and you don’t want metal shavings or fiberglass dust getting inside your home—or your lungs.

Safety Gear for Drilling Exterior Doors

Here’s a story: I once thought I could rush through a quick deadbolt install without goggles. The bit caught on a steel door, and I got a face full of hot metal flakes. Lesson learned.

Safety matters, even for “simple” drilling. Here’s what you’ll want on hand:

- Safety glasses: Always. Even a tiny chip can cause real damage.

- Dust mask or respirator: Especially important with fiberglass, where dust can irritate your lungs (and itch like crazy if it gets on your skin).

- Work gloves: Not just for grip, but to protect from sharp metal edges after drilling.

- Ear protection: Drilling through metal is loud, and hammer drills can really scream—especially in an echoey entryway.

You’ve got to balance precision and patience. Rushing because you’re uncomfortable or cutting corners on safety slows you down in the long run.

Troubleshooting Common Drilling Problems

Even with the right gear, tough doors like to throw curveballs. Here’s how to handle a few common headaches:

- Bit won’t go through/keeps dulling: Double-check if your bit is made for the material. If not, swap it out. For steel, try lowering your drill speed—you want a slow, steady push, not a scorched mess.

- Hole is jagged or chipped: For fiberglass, slow down and use painter’s tape. For wood, try stepping up to a sharper bit or using a backer board to support the exit hole.

- Drill bit keeps “walking” off mark: Use a center punch or self-centering guide to anchor your bit before starting. Don’t skip this—one slip can ruin the look of your entryway.

- Drill battery dies mid-job: Keep a backup battery on hand, especially if you’re using a cordless model for multiple holes. Nothing kills momentum faster than waiting for a recharge.

If you mess up (it happens!), wood putty or fiberglass repair kits can hide small goofs. For steel, touch-up paint is your best cover-up.

Comparing Top Brands for Exterior Door Drilling Tools

You’ll see names like DeWalt, Bosch, Milwaukee, and Makita everywhere. Do brands matter? In my opinion, yes—especially when you’re drilling into something costly.

DeWalt’s cordless drills are known for their battery life and easy handling. Bosch makes some of the toughest drill bits for steel and fiberglass, with coatings that genuinely last longer. Milwaukee tends to have the most powerful hammer drills, which cut down your drilling time on steel doors. Makita’s gear is lightweight and balanced, which can be a relief if you’re drilling dozens of holes in a row.

Honestly, unless you’re drilling professionally, you don’t need the absolute top-of-the-line. But it pays to get at least a mid-range drill and bits—not just the cheapest set in the hardware aisle. You’ll get cleaner results, fewer headaches, and tools that actually sync with future home projects.

Alternatives and When to Call a Professional

Sometimes, even the best tools for precision drilling on difficult exterior door materials aren’t enough. If your door has electrical components, embedded code systems, or you need to reset and pair a smart lock seamlessly, calling a pro might be the smartest move.

Here’s why: Some doors have reinforced security plates or hidden metal cores that regular drills can’t handle. Or you might need to drill into a tight spot near glass, where one slip could crack the pane. Locksmiths and door specialists have industrial-grade tools and templates, and they’ll often warranty their work.

Still want to DIY? Many brands (Schlage, Kwikset) offer universal lock install kits with step-by-step guides and all the right bits—in some cases, even a battery-powered hole saw made just for doors. It’s not the same as hiring out, but it gets you much closer to a professional finish.

Wrapping Up: Get the Right Tools, Get Better Results

Drilling precise holes in tough exterior doors doesn’t have to be stressful or risky. The secret is matching the right drill, bits, and accessories to the material in front of you—whether that’s a steel entry, a fiberglass slab, or solid-core wood. Don’t be shy about spending a little more for a quality tool or a smarter accessory; it pays off quickly when you see smooth, accurate holes and securely mounted hardware.

Remember, even with the best tools for precision drilling on difficult exterior door materials, patience and prep make all the difference. Take your time, double-check your marks, and put safety first. Your future self—and your front door—will thank you.